In the dynamic landscape of automation and robotics, the evolution of motor driver integration equipment has been nothing short of revolutionary. Traditional motor drivers, functioning as standalone components, necessitated intricate wiring and complex control systems. However, the trajectory of technological progress has given rise to a paradigm shift, ushering in integrated solutions that amalgamate motor drivers with state-of-the-art technologies such as microcontrollers and sensor systems.

The Shift from Standalone to Integrated Solutions

Historically, motor drivers operated in isolation, necessitating external control systems and extensive cabling. The advent of integrated motor driver solutions marks a departure from this norm. For instance, the integration of microcontrollers directly into motor driver systems has streamlined the overall design. This not only reduces the physical footprint but also simplifies the control architecture, paving the way for more efficient and compact systems.

Examples of Integrated Motor Driver Technologies

a. Microcontroller Integration

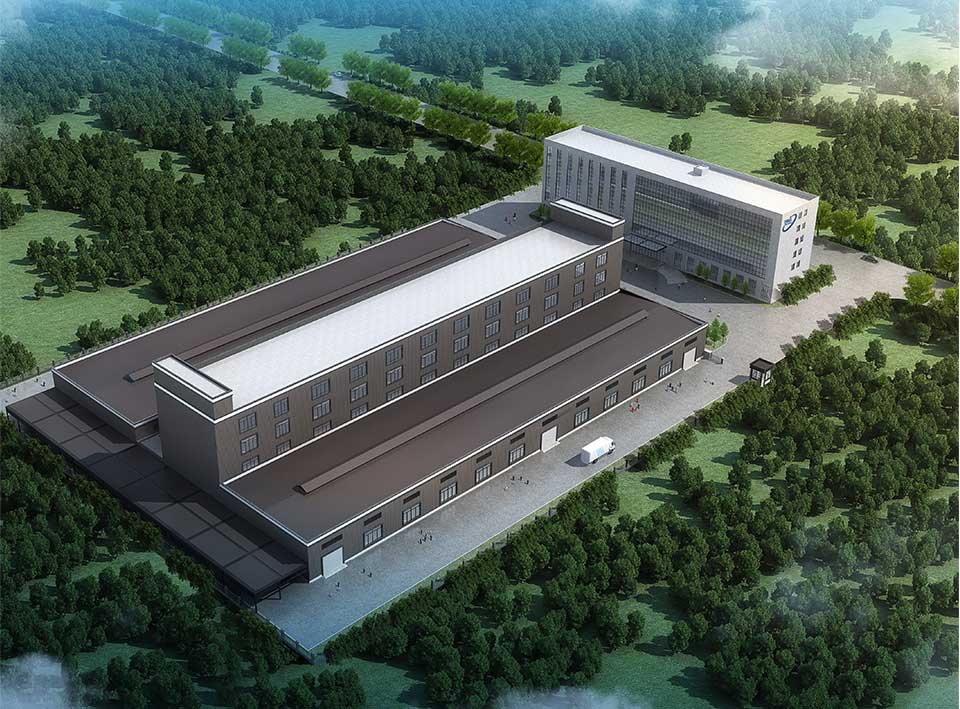

One exemplary instance of motor driver integration involves the incorporation of microcontrollers. Zhejiang Qiyue Mechanical Technology Co.,ltd. have introduced motor driver ICs (Integrated Circuits) with embedded microcontrollers. These integrated solutions seamlessly combine motor control algorithms with microcontroller functionalities, allowing for enhanced processing capabilities and precise control in a single compact package.

b. Sensor Fusion

Innovations in sensor technology have also played a pivotal role in the evolution of integrated motor driver systems. Zhejiang Qiyue Mechanical Technology Co.,ltd. have developed motor driver ICs that incorporate advanced sensor fusion techniques. By integrating encoders or Hall-effect sensors directly into the motor driver, these systems can provide real-time feedback, enabling precise control and position monitoring without the need for external sensors.

2.Key Features and Benefits of Integrated Motor Driver Systems

The surge in popularity of integrated motor driver systems can be attributed to a myriad of features and benefits, transforming the operational landscape across various industries. One of the primary advantages lies in the reduction of space and complexity associated with traditional setups. Integrated solutions, by combining motor drivers with essential components, facilitate the creation of more streamlined and compact systems, a crucial aspect in applications where space optimization is paramount.

Compact Design and Space Optimization

The automotive industry provides an excellent example of the benefits of compact design. Integrated motor drivers find applications in electric vehicles (EVs) where space constraints are significant. By consolidating motor drivers, microcontrollers, and power electronics into a single module, automakers can optimize the layout of EV components, leading to more efficient use of space within the vehicle.

Advanced Control Algorithms

Integrated motor driver systems often come equipped with advanced control algorithms that significantly enhance overall system performance. For instance, companies like Zhejiang Qiyue Mechanical Technology Co.,ltd. have developed motor driver ICs with proprietary control algorithms. These algorithms enable precise torque control, speed regulation, and even adaptive control strategies, ensuring optimal motor performance across varying operating conditions.

Simplified Installation and Maintenance

The streamlined nature of integrated motor driver systems extends beyond design benefits to encompass ease of installation and maintenance. With fewer components and simplified wiring, these systems reduce the likelihood of errors during installation. Additionally, maintenance becomes more straightforward, as technicians can quickly identify and replace a single integrated module, minimizing downtime and overall operational disruptions.

The versatility of integrated motor driver systems makes them indispensable across diverse industries, ranging from manufacturing and automotive to robotics and aerospace. As industries continue to embrace automation, the demand for integrated motor driver solutions is projected to soar, propelling further innovation in this dynamic field.

Diverse Applications Across Industries

a. Manufacturing

In manufacturing, integrated motor driver systems find applications in conveyor systems, robotic arms, and precision machining equipment. The compact design and advanced control features contribute to increased production efficiency and precision.

b. Robotics

The robotics industry benefits from integrated motor driver systems in the development of autonomous robots and drones. These systems enable precise control of motors, ensuring smooth and accurate movements essential for tasks such as object manipulation and navigation.

Connectivity and Intelligent Features

Looking toward the future, trends in motor driver integration equipment are expected to gravitate towards enhanced connectivity and intelligent features. The integration of Industrial Internet of Things (IIoT) platforms and cloud-based systems is poised to revolutionize how motor-driven systems are monitored and controlled.

Integration with IIoT Platforms

Companies like Zhejiang Qiyue Mechanical Technology Co.,ltd. are actively integrating motor drivers with IIoT platforms. This integration enables real-time monitoring of motor performance, predictive maintenance based on data analytics, and remote control capabilities. For example, in a manufacturing facility, an integrated motor driver system linked to an IIoT platform can provide insights into motor health, helping schedule maintenance before a potential failure occurs.

Machine Learning for Optimal Control Strategies

The future of motor driver integration also holds promise for the incorporation of machine learning algorithms. By leveraging data from sensors and historical performance, these algorithms can optimize motor control strategies. For instance, in a smart factory environment, machine learning algorithms can adapt motor control parameters based on production demand, energy efficiency goals, and environmental conditions.

The integration of motor driver equipment stands as a transformative force in the landscape of automation and robotics. As technological progress marches forward, integrated systems will continue to evolve, offering a spectrum of features and benefits for industries striving to enhance operational efficiency and remain at the forefront of technological innovation. The trajectory of motor driver integration promises not only increased efficiency but also opens up new frontiers in intelligent and connected systems, shaping the future of automation.