In today's rapidly evolving industrial landscape, automation has become a cornerstone for achieving higher productivity and precision. Among the various automation solutions available, robotic arms have gained widespread popularity for their versatility and efficiency in performing a multitude of tasks. The Irregular Workpiece Punching and Deburring Robot Arm YT2300-30-6A is a remarkable example of cutting-edge automation technology designed to excel in the realm of sheet metal processing.

The YT2300-30-6A is a state-of-the-art robotic arm developed by industry leader, Techtron Robotics. This advanced robotic arm is specifically tailored for applications involving irregular workpieces, offering unparalleled precision and adaptability in punching and deburring tasks.

2.Key Features and Advantages of the YT2300-30-6A

Versatile Workpiece Adaptability:

The YT2300-30-6A boasts exceptional adaptability, making it ideal for punching and deburring irregularly shaped workpieces. Its advanced vision system, equipped with high-resolution cameras and cutting-edge image processing algorithms, allows the robot to identify and locate workpiece edges and features accurately. This capability ensures precise and consistent processing, regardless of the shape or size of the workpiece, reducing the need for manual adjustments and human intervention.

The ability to adapt to various workpiece shapes is crucial in the modern manufacturing landscape. Irregular workpieces often pose challenges for traditional automation systems, which require frequent reprogramming and manual intervention to handle diverse shapes. The YT2300-30-6A overcomes this limitation by leveraging its sophisticated vision system.

The high-resolution cameras provide a clear and detailed view of the workpiece, and the advanced image processing algorithms allow the robot arm to recognize workpiece edges and contours with precision. This means that whether the workpiece is a complex, irregular shape or a standard piece, the YT2300-30-6A can adapt and execute the required tasks flawlessly. The reduction in manual adjustments not only saves time but also ensures consistent quality and minimizes the risk of errors.

High-Speed Performance:

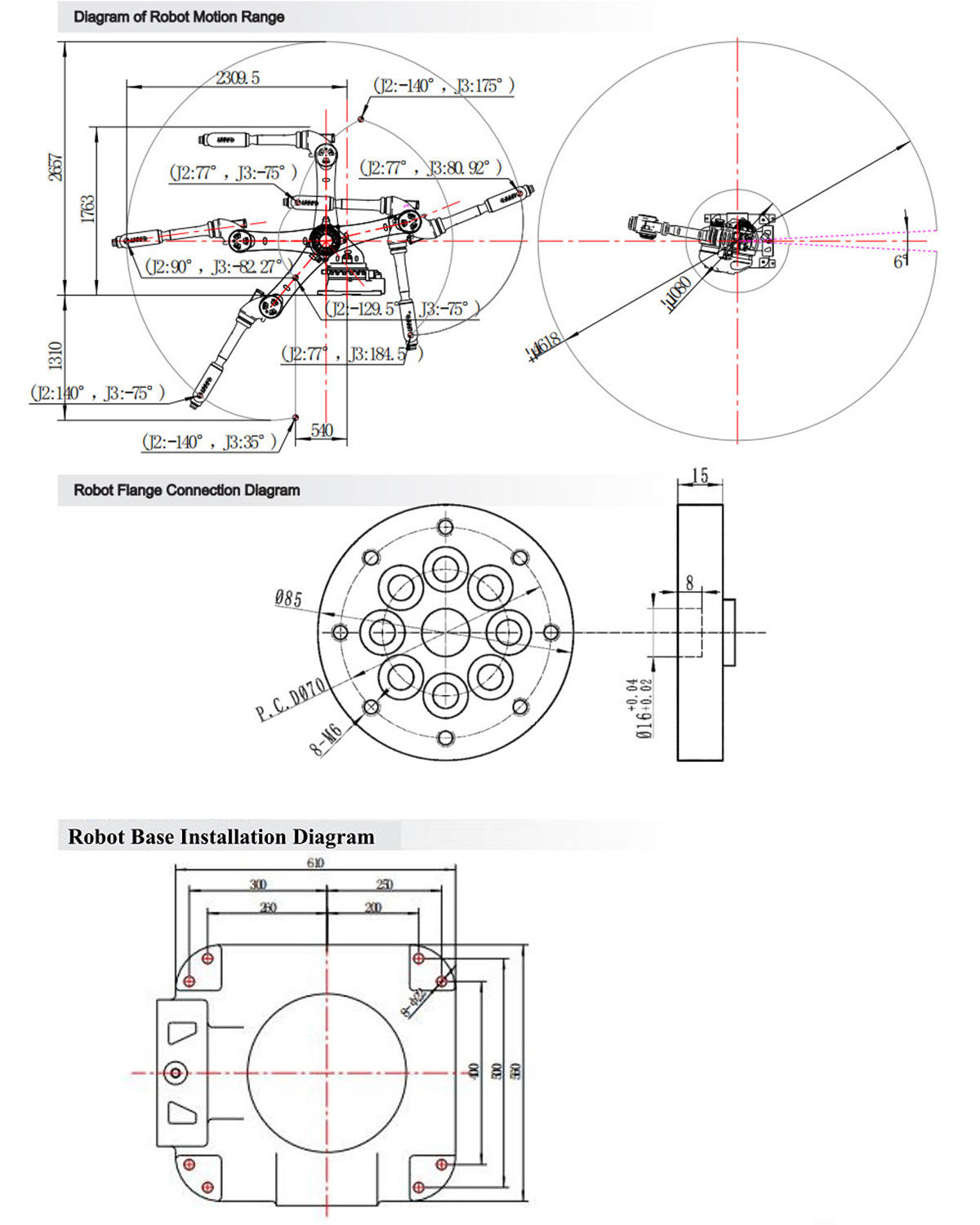

One of the standout features of the YT2300-30-6A is its impressive speed and agility. The robot arm is equipped with a robust 6-axis design and high-performance motors, enabling it to execute tasks swiftly and with exceptional accuracy. This translates to reduced cycle times and increased production throughput, allowing manufacturers to meet demanding production schedules while maintaining consistent quality.

Speed and agility are paramount in modern manufacturing. The YT2300-30-6A's 6-axis design provides exceptional flexibility and maneuverability. Each axis allows precise control of the robot's movements, ensuring that it can reach and operate on the workpiece from any angle with remarkable dexterity.

The high-performance motors, carefully engineered to provide both power and precision, ensure that the robot arm moves swiftly while maintaining accurate control. This not only reduces cycle times, increasing productivity, but also contributes to the overall efficiency of the manufacturing process.

Moreover, the YT2300-30-6A's speed is particularly advantageous in industries with high-volume production. The ability to complete tasks quickly and accurately allows manufacturers to keep up with demanding production schedules and respond to market fluctuations promptly.

Advanced Deburring Capabilities:

Deburring is a crucial step in sheet metal processing, as it ensures that workpieces are free from sharp edges or burrs that could compromise safety and product quality. The YT2300-30-6A is equipped with specialized deburring tools and algorithms, ensuring that all edges are deburred precisely and uniformly. The robot arm's adaptability extends to deburring, making it an invaluable asset for industries where precise edge finishing is vital.

Deburring, although essential, has traditionally been a labor-intensive and time-consuming task. Human operators often perform this task manually, which can be inconsistent and prone to errors. The YT2300-30-6A revolutionizes this aspect of sheet metal processing by incorporating advanced deburring capabilities.

The robot arm's deburring tools are specifically designed for efficiency and precision. These tools can access intricate or difficult-to-reach areas of a workpiece, ensuring that all edges, nooks, and crannies are deburred uniformly. This not only enhances the safety of the end product by eliminating sharp edges but also contributes to the overall aesthetics and quality of the workpiece.

The deburring algorithms are a crucial component of the YT2300-30-6A's deburring capabilities. These algorithms are finely tuned to ensure that the right amount of material is removed, avoiding over-deburring or under-deburring, which can compromise the workpiece's integrity. The result is a consistently high-quality finish on every workpiece, regardless of its shape or complexity.

3.Increased Efficiency and Cost Savings

Reduced Labor Costs:

By automating irregular workpiece punching and deburring, the YT2300-30-6A minimizes the need for manual labor, allowing manufacturers to save on labor costs and allocate their workforce to more value-added tasks. This not only reduces operational expenses but also minimizes the risk of human error.

One of the primary advantages of investing in automation, such as the YT2300-30-6A, is the significant reduction in labor costs. In traditional manufacturing processes, labor-intensive tasks like punching and deburring irregular workpieces often require skilled operators. By automating these tasks, the YT2300-30-6A eliminates the need for continuous manual labor, freeing up human resources for more complex and value-added roles within the production process.

Furthermore, human error, a common factor in manual operations, is minimized with the use of the YT2300-30-6A. The robot arm operates with precision and consistency, reducing the likelihood of mistakes that can lead to defects, rework, or safety concerns. This translates into cost savings and a more efficient production process.

Enhanced Consistency and Quality:

Robotic automation ensures consistent, high-quality results in every cycle. The YT2300-30-6A's precision and adaptability minimize the likelihood of errors and defects in workpiece processing, guaranteeing that the final products meet the required standards.

Consistency and quality are paramount in manufacturing, especially when it comes to sheet metal processing. Inconsistencies in workpiece punching or deburring can result in defects, safety hazards, and the need for rework, all of which can be costly and time-consuming.

The YT2300-30-6A excels in providing consistent, high-quality results with every cycle. The robot arm's precision and adaptability, coupled with its advanced vision system and deburring capabilities, ensure that workpieces are processed with the utmost accuracy. Whether the workpiece is a simple shape or a highly irregular form, the robot arm executes the tasks flawlessly, eliminating the variability associated with human operators.

This consistency has a direct impact on the quality of the end product. Manufacturers can confidently deliver workpieces that meet the required standards and specifications, reducing the risk of defects, rework, and customer dissatisfaction. This not only saves time and resources but also enhances the reputation of the manufacturer for producing high-quality products.

Improved Production Output:

The combination of speed and precision in the YT2300-30-6A results in increased production output. Manufacturers can process more workpieces in less time, meet tight production schedules, and respond swiftly to changing market demands.

Efficiency in production output is a critical factor in staying competitive in today's manufacturing landscape. The YT2300-30-6A's combination of speed and precision translates into increased productivity, allowing manufacturers to process more workpieces within the same time frame. This capability is particularly valuable in industries with high-volume production requirements.

The high-speed performance of the robot arm reduces cycle times, ensuring that workpieces are processed swiftly and accurately. As a result, manufacturers can meet tight production schedules and respond promptly to market demands. Whether it's a sudden increase in orders or a need to adapt to changing customer preferences, the YT2300-30-6A provides the flexibility to scale production output efficiently.

The increased production output has a direct impact on a manufacturer's bottom line. The ability to process more workpieces within the same time frame enhances revenue potential while maintaining operational efficiency. This results in a higher return on investment for the YT2300-30-6A and positions the manufacturer for growth and success in a competitive market.