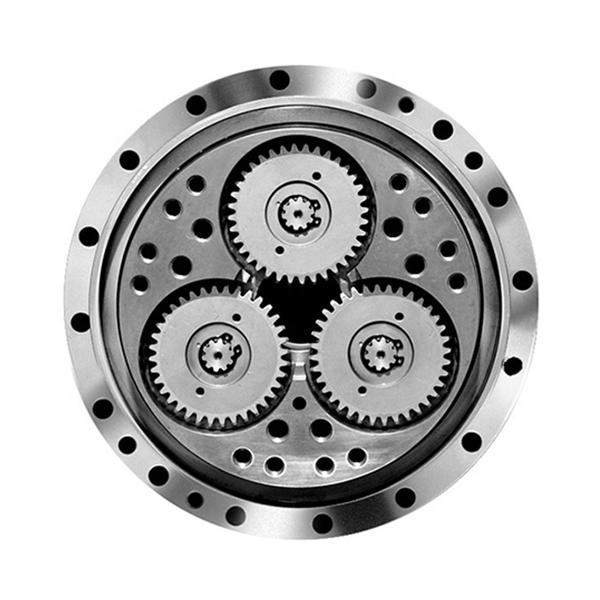

Gearbox failure is the most common cause of mechanical failure. In order to prevent gearbox failure, engineers must determine the cause of the failure. There are many factors that cause gearbox failure. Therefore, a gearbox failure and maintenance engineer has to consider all the reasons for the gearbox failure in order to confirm the real cause. Similarly, considering the possibility of gearbox failure in the process of gear design can help the design of the gearbox have the advantages of reliability and durability.

Different potential causes of gearbox failure:

As the assembly of the mechanical equipment system, the gearbox has suffered multiple failure factors. The following are some potential reasons recognized by industry experts.

Wear and tear: every moving mechanical part is exposed to wear and loss. Gearboxes are no exception to this problem. Gearboxes may experience multiple types of wear, and over time, it may lead to failures, gear damage, or gear assembly failure.

Abrasive wear: This happens because the parts of the two gearbox assemblies rub against each other. It will cause radial scratches and small grooves. If abrasive wear occurs excessively at the top and root of the gear, it becomes the cause of gear failure.

Corrosion and wear: The metal surface of the gearbox is exposed to chemicals, oil and rust, and this will cause corrosion and wear. Corrosion wear leads to deterioration of gear materials. This can cause sudden fracture of the gear surface.

Insufficient lubrication: Insufficient lubrication increases the wear of the gearbox during operation. Friction generates heat, pitting (contact fatigue), and abrasive wear, which can cause gear failure.

Misalignment: Gear assembly is designed for specific meshing curve, contact point, suitable shaft, torque and backlash. Therefore, a slight misalignment of any component of the gearbox will cause overlap of component propagation paths. This can lead to assembly blockage, sudden and permanent failure of the gearbox.

Overload: Because the gear is loaded from different directions. However, gears and gear assemblies are designed for specific load tolerance. If the gear assembly is overloaded, it may be subjected to bending fatigue, which can cause tooth fracture, cracks in the tooth tip and root, and complete failure under extreme load conditions. Bending fatigue may reduce the impact resistance of gears and shafts, and being embedded on them may cause sudden failure.

Installation and handling errors: Installation errors can cause transient failure of the gearbox assembly. 17.7% of gearbox failures are caused by installation errors. However, inappropriate processing or rough processing is a processing error. If these processing errors are not resolved quickly, they will destroy the gearbox assembly for a long time. 2.8% of gearbox failures are due to handling errors.

Wear: This is the transfer of material from gear to pinion, or vice versa. Wear leads to poor gear surface composition, poor surface finish and tooth profile damage, which is a cause of gear damage.

Frosting: Due to excessive heat, when the lubricating layer ruptures, frosting occurs. It causes micropitting, which increases wear and eventually gear failure.

Surface contamination: Gear surfaces with dust and metal chips will damage the surface. It will create scratches on the surface and will increase wear and heat, and this will cause gearbox failure.