1. Harmonic reducer technology

The ADH-I hat-type harmonic reducer is a precision mechanical device that can achieve high-precision motion control in a variety of applications. An understanding of harmonic reducer technology is crucial for industry practitioners and professionals in related fields.

1.1 Working principle

The working principle of the hat-type harmonic reducer is the basis for its excellent performance. This reducer uses the principle of harmonic vibration to achieve high-precision motion control through elastic deformation. This working principle consists of three main components: input wave generator, harmonic gear, and output structure.

The input wave generator is the part that drives the harmonic reducer, usually an oval gear. As the input wave generator rotates, it induces harmonic vibrations through its elliptical contour, which is transmitted to the harmonic gear. There are internal gears and external gears on the harmonic gear, and the cooperation between them determines the reduction ratio. Finally, the motion of the harmonic gear is transmitted through the output structure to the output shaft.

This working principle has multiple advantages, including high torque output, high-precision position control and low backlash design. This makes the ADH-I hat-type harmonic reducer an ideal choice in many fields.

1.2 Manufacturing materials and processes

The performance and quality of ADH-I hat-type harmonic reducer are significantly affected by materials and manufacturing processes. Understanding these aspects can help manufacturers continually improve their products and ensure they meet the highest standards.

Harmonic reducers are usually made of high-strength alloy steel to ensure their durability under high load conditions. These materials undergo precision machining, including CNC machining, heat treatment and surface treatment to ensure high accuracy and low backlash. Precision machining is critical to the performance of the reducer, as any manufacturing inaccuracies can result in reduced performance.

The manufacturing process also includes accurate assembly processes. The internal components of a harmonic reducer must be assembled to extremely high standards to ensure its reliability and performance. This includes the correct installation of gears, bearings and seals to reduce friction and wear.

1.3 High-precision applications

ADH-I hat-type harmonic reducer has a wide range of high-precision applications in robotics, precision instruments, solar tracking systems and other fields. These applications require accurate position and speed control to ensure system performance and reliability. Here are examples of a few key areas:

1.3.1 Robotics

In modern robotics, high-precision motion control is crucial. The ADH-I hat-type harmonic reducer provides excellent positional accuracy and controllability, allowing robots to perform precision tasks such as assembly, welding, and even surgery. During surgical procedures, the high precision of the reducer ensures precise operation and reduces patient risk.

1.3.2 Precision instruments

Many scientific experiments and precision instruments require high-precision motion control to ensure data accuracy. ADH-I hat-type harmonic reducer is widely used in fields such as optical instruments, precision measurement equipment, and semiconductor manufacturing equipment, providing excellent performance and reliability.

1.3.3 Solar tracking system

In the solar industry, solar tracking systems can improve the energy collection efficiency of solar panels. Harmonic reducers are used to control the orientation of these systems to ensure that the solar panels are always facing the sun. High-precision motion control can maximize the use of solar resources and increase energy production.

2. Application areas

The wide range of applications of harmonic reducers make them an indispensable component in many industries.

2.1 Robotics

Robotics is a key application area for harmonic reducers. From automated robots in manufacturing to surgical robots in the medical field, high precision and controllability are core requirements for robots. The harmonic reducer ensures that the robot can perform complex tasks through its low backlash and high precision characteristics. In manufacturing, this means higher production efficiency and product quality, while in the medical field, it can reduce surgical risks and improve surgical accuracy.

2.2 Industrial automation

In industrial automation, harmonic reducers are widely used in automated equipment such as transmission robotic arms, conveying systems, and packaging equipment. These applications require high torque output and high-precision position control to ensure high efficiency and accuracy of the production line. Harmonic reducers can meet these needs, thereby increasing the efficiency of the production line and reducing operating costs.

2.3 Solar tracking system

The solar industry is another important application area where harmonic reducers play a role. Solar tracking systems need to ensure that solar panels are always facing the sun to maximize energy collection. Harmonic reducers are used to control the directional adjustment of the tracking system to ensure highly accurate solar tracking. This helps improve the energy efficiency of solar systems and reduces energy costs.

3. Future trends

The harmonic reducer manufacturing industry is constantly evolving and innovating, facing some exciting future trends. Below is a more detailed look at future trends.

3.1 Intelligence and automation

In the future, harmonic reducers will integrate more intelligent and automated functions to meet the needs of Industry 4.0 and autonomous driving. This includes sensor technology and remote monitoring to monitor and adjust the performance of the reducer in real time. Intelligent reducers will be able to automatically adapt to different workloads and environmental conditions, improving reliability and maintainability.

3.2 Advances in materials and manufacturing technologies

Continuous advances in materials science and manufacturing technology will further improve the performance and reliability of harmonic reducers while reducing manufacturing costs. The development of new materials and innovative manufacturing processes will make harmonic reducers lighter and more durable. This helps meet increasingly stringent performance requirements and reduces maintenance costs.

3.3 Sustainability

In terms of sustainability, manufacturers will continue to strive to develop more energy-efficient and environmentally friendly products. Reducing energy consumption, reducing resource waste, and reducing environmental impact will be key goals for future harmonic reducer manufacturing. This may include more efficient design, more sustainable material selection and the adoption of green production processes.

The

ADH-I hat-type harmonic reducer manufacturing industry has extensive and deep knowledge in technology, applications and future trends. This knowledge is invaluable to manufacturers, engineers and domain experts, helping them to continuously improve their products to meet increasingly stringent performance requirements while contributing to sustainability and environmental goals. Harmonic reducers will continue to play a key role in many fields and continue to evolve with the development of technology and markets.

![]()

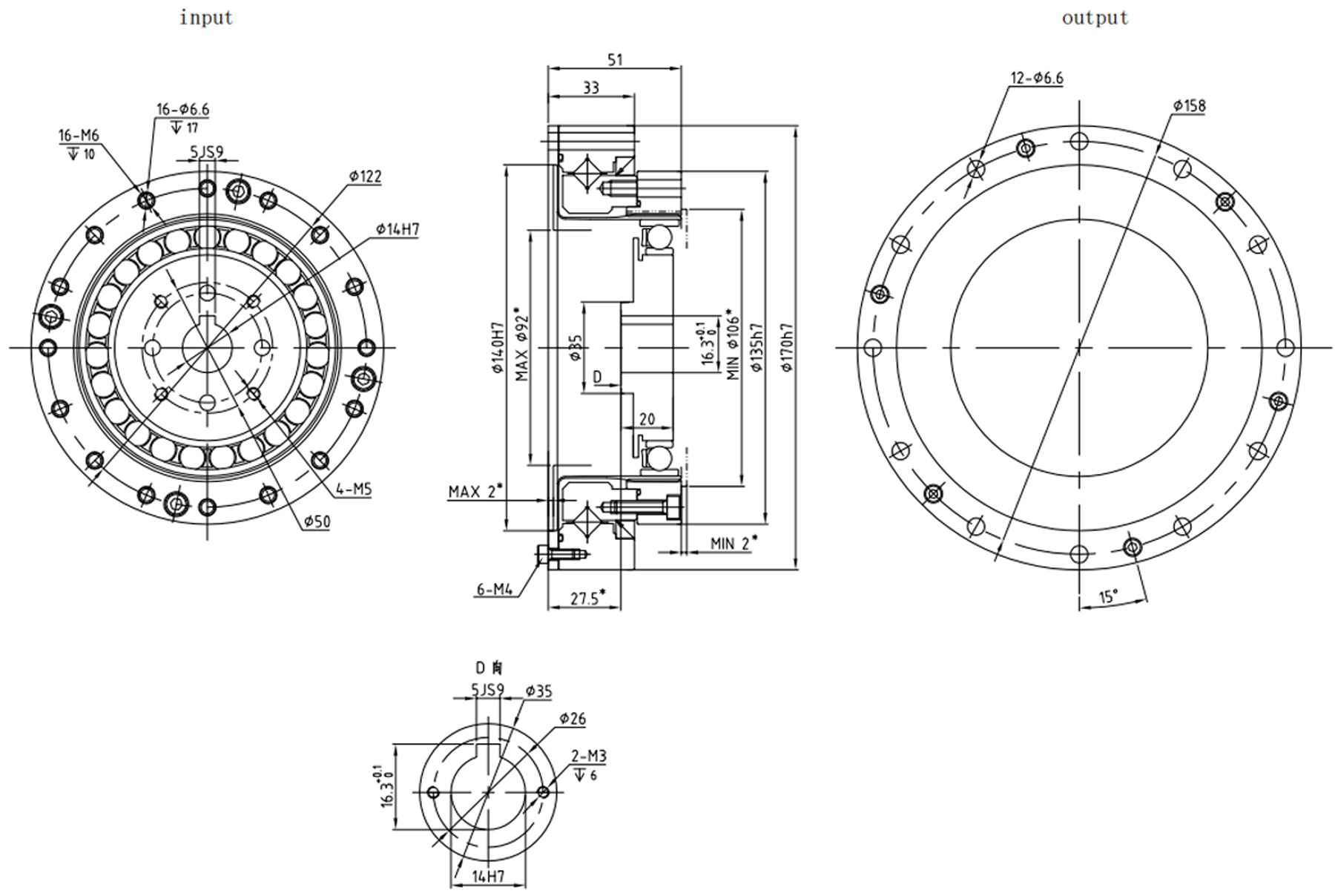

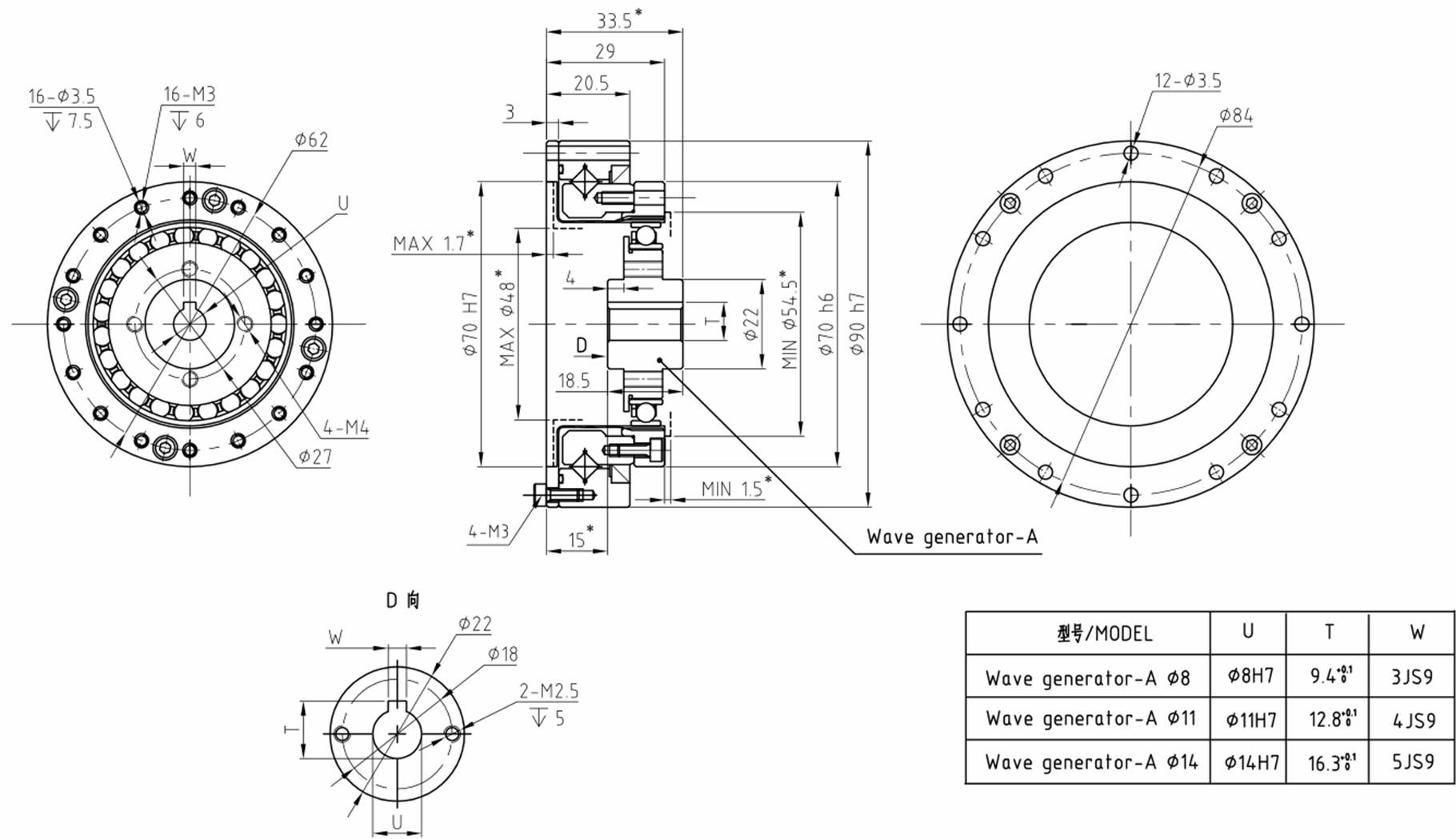

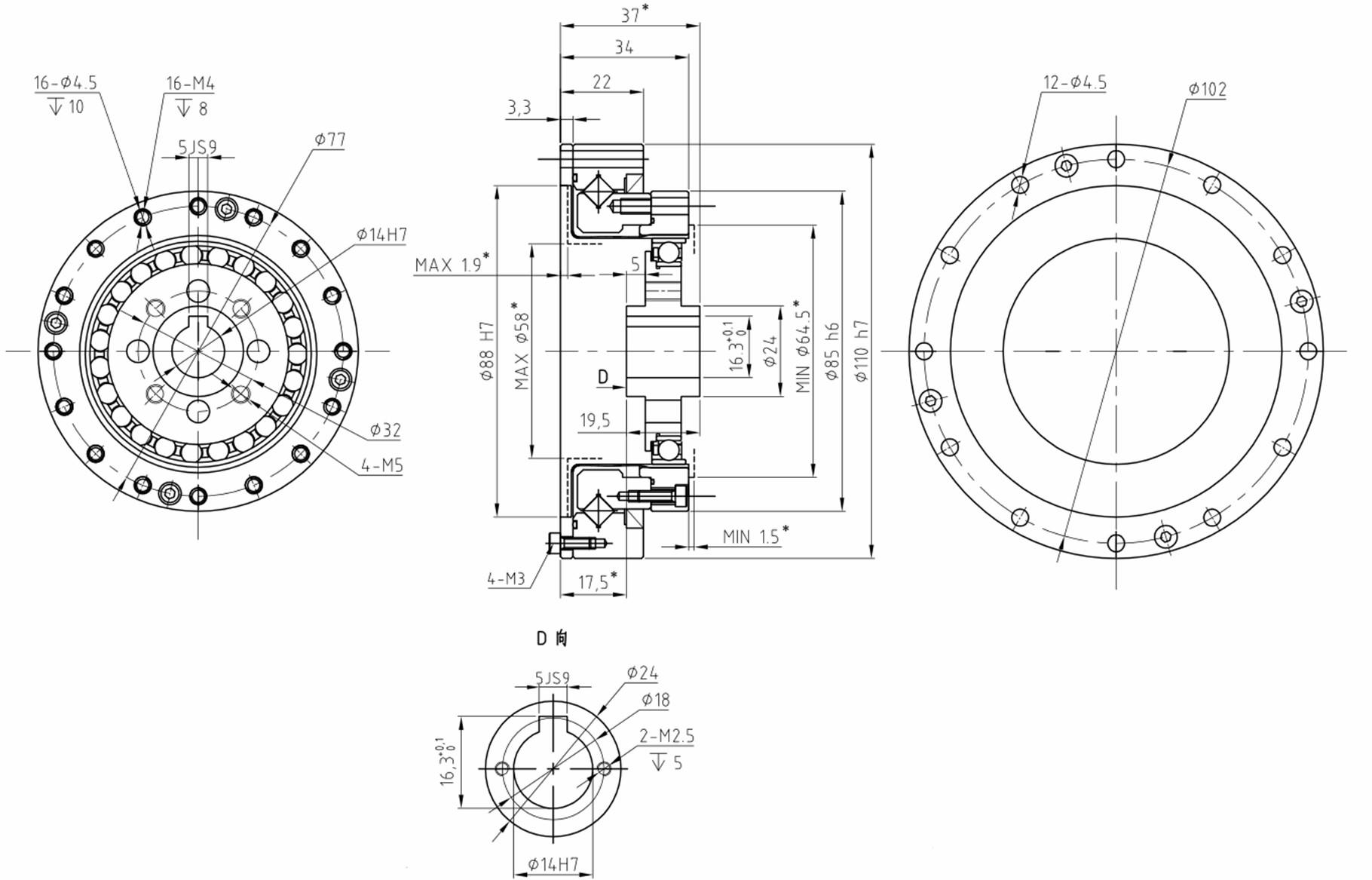

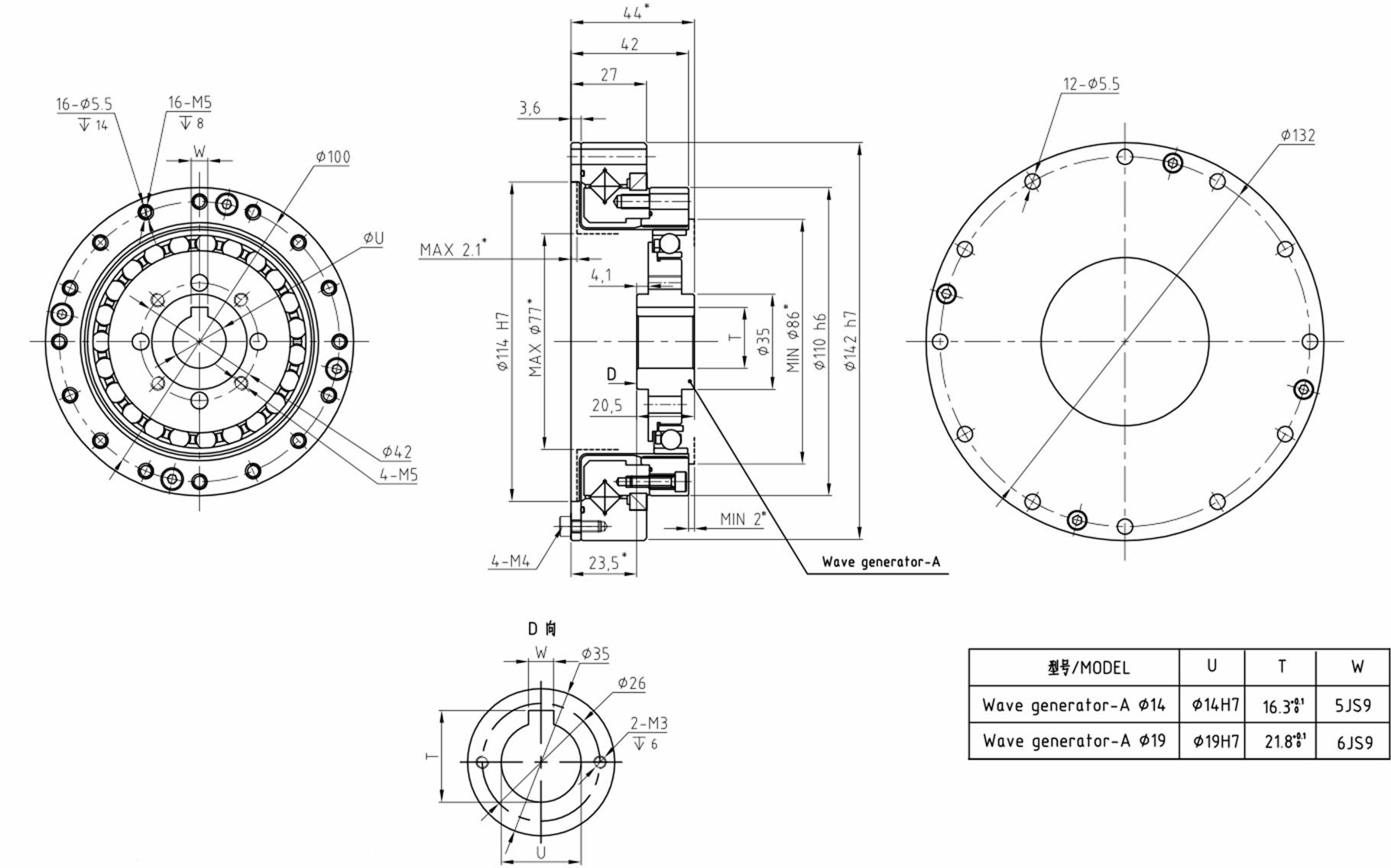

ADH-40-*-I/ADHG-40-*-I

ADH-40-*-I/ADHG-40-*-I