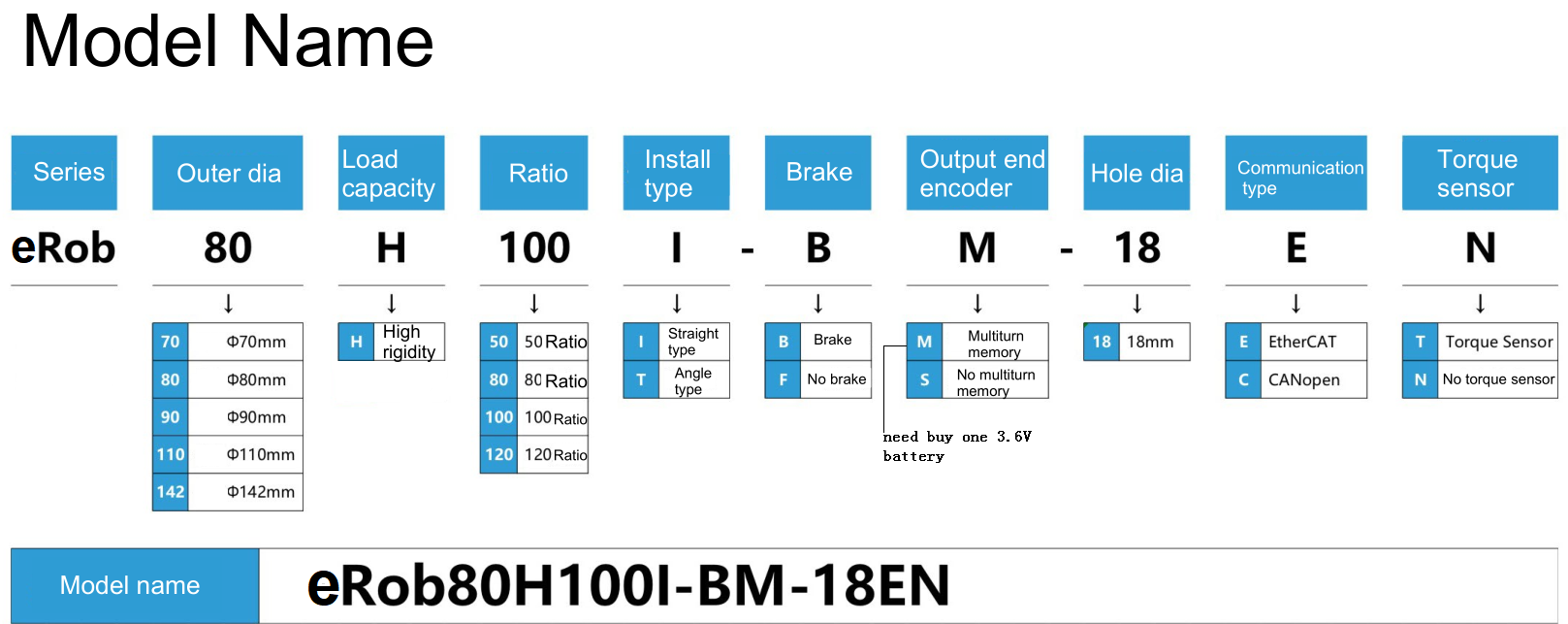

Item No.: eRob 70I/90I

Place of Origin:Zhejiang

Brand Name:Arcsec Drive

Brake:Friction damped brake

Marketing Type:Ordinary Product

Core Components:Bearing

Warranty of core components:1 YEAR

After-sales Service Provided:Free spare parts, Video technical support, Online support

combined with motor, reducer, encode and so on. High precision;small size , easy essemble

|

model |

eRob 70-I |

eRob 80-I |

eRob 90-I |

eRob 110-I |

eRob 142-I |

||||||||||||||

|

Harmonic Drive-Ratio |

14-50 |

14-80 |

14-100 |

17-50 |

17-80 |

17-100 |

20-50 |

20-80 |

20-100 |

25-50

|

25-80

|

25-100

|

25-120

|

32-50

|

32-80

|

32-100

|

32-120

|

||

|

Start-stop peak torque(Nm) |

18/23 |

23/30 |

28/36 |

34/44 |

43/56 |

54/70 |

56/73 |

74/96 |

82/107 |

98/127 |

137/178 |

157/204 |

167/217 |

216/281 |

304/395 |

333/433 |

353/459 |

||

|

Rated torque(Nm) |

7 |

10 |

10 |

21 |

29 |

31 |

33 |

44 |

52 |

51 |

82 |

87 |

87 |

99 |

153 |

178 |

178 |

||

|

Maximum allowable moment torque(Nm) |

46 |

61 |

70 |

91 |

113 |

143 |

127 |

165 |

191 |

242 |

332 |

369 |

395 |

497 |

738 |

841 |

892 |

||

|

Peak speed at output end(RPM) |

60 |

37.5 |

30 |

60 |

37.5 |

30 |

60 |

37.5 |

30 |

40 |

25 |

20 |

16.7 |

40 |

25 |

20 |

16.7 |

||

|

Motor power(W) |

100 |

200 |

400 |

750 |

1000 |

||||||||||||||

|

voltage(V) |

48 (士10%) |

48 (士10%) |

|||||||||||||||||

|

Rated current(A) |

3.3 |

6.9 |

11 |

20 |

26 |

||||||||||||||

|

Peak current(A) |

11 |

16.8 |

29 |

40 |

56 |

||||||||||||||

|

Output encoder resolution |

19Bit |

||||||||||||||||||

|

Repeat/absolute positioning accuracy |

±10/45arc sec |

||||||||||||||||||

|

Communication bus |

EtherCAT/CANopen |

||||||||||||||||||

|

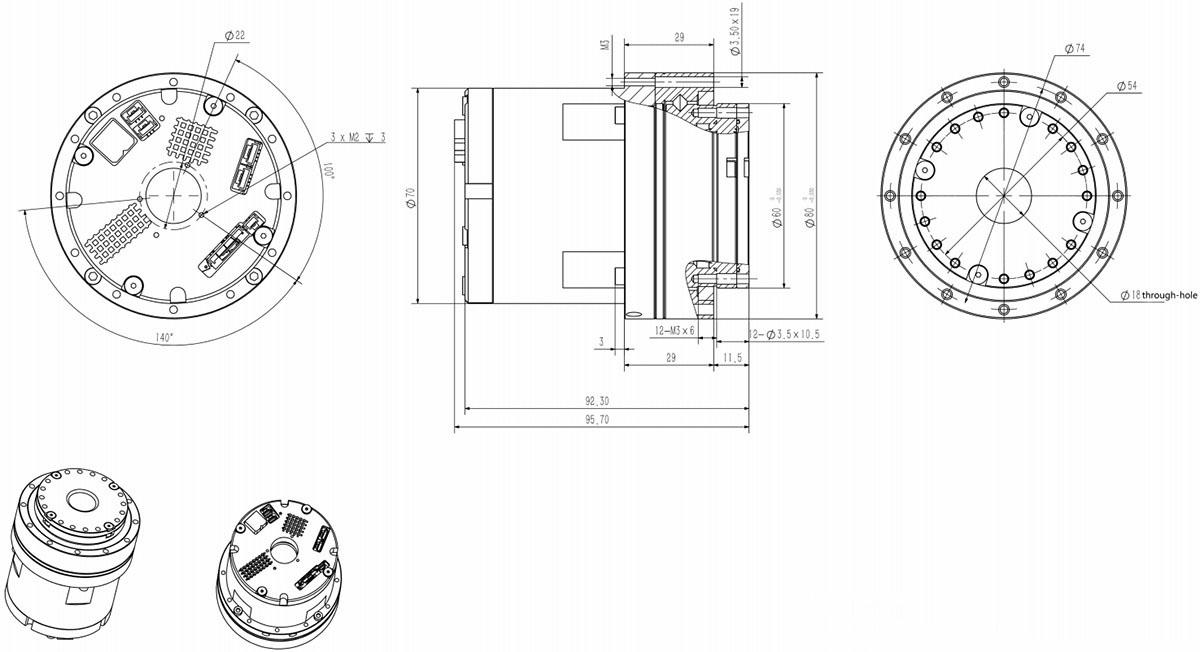

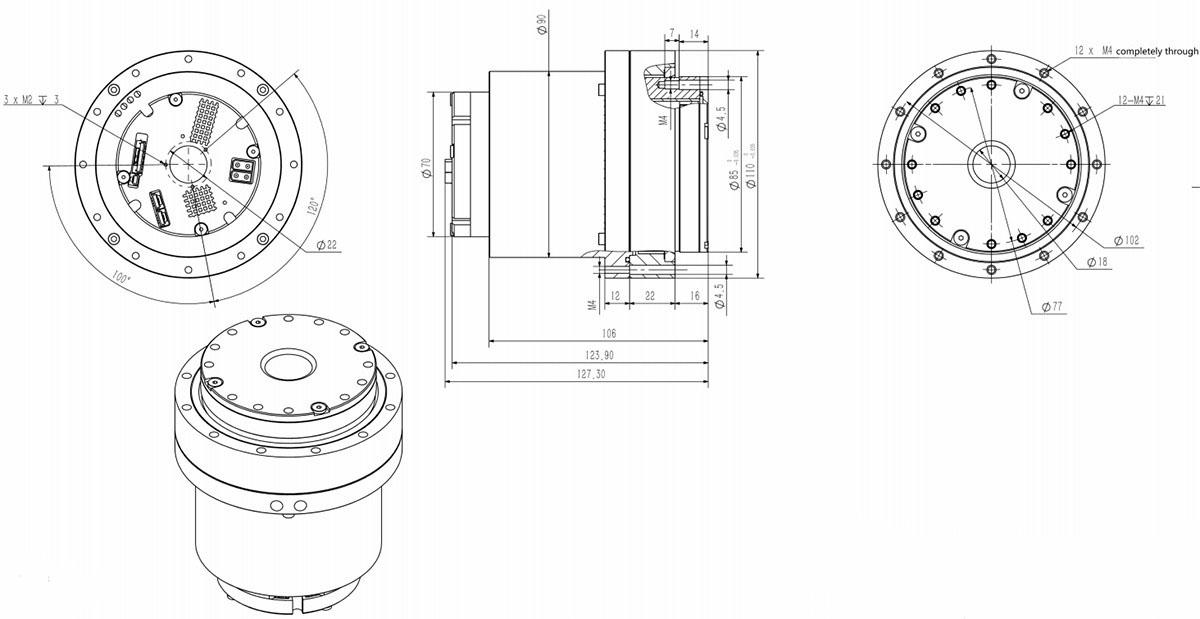

Outside diameter * length * through hole(mm) |

70x81x18 |

80x95x18 |

90x102x18 |

110x127x18 |

142x137x18 |

||||||||||||||

|

Weight(kg) |

0.98 |

1.4 |

2.1 |

3.3 |

6.7 |

||||||||||||||

|

Interface design |

Full differential interface design, strong anti-interference ability, double anti-loose plug, can be connected in series. |

||||||||||||||||||

|

Brake |

Friction damping brake(optional) |

||||||||||||||||||

|

IP grade |

IP54 |

||||||||||||||||||

eRob 70I

eRob 70I

eRob 90I

Zhejiang Qiyue Mechanical Technology Co., Ltd. as a Custom Robot Modular Joints Manufacturers is your complete source for gear reducers, actuator,rotary table, robot arm, and other innovative products used in automation technology.With one of the largest product offerings in the motion control industry as well as the engineering expertise and manufacturing capabilities to provide customized solutions, Arcsec Drive can help with your application.Being flexible to meet the needs of customer requests and great service are what set Arcsec Drive apart from the rest.