1. Application fields of grinding robots

Grinding robots have a wide range of applications in the manufacturing industry, where they can improve production efficiency, quality and work environment safety. Here are some common application areas for grinding robots:

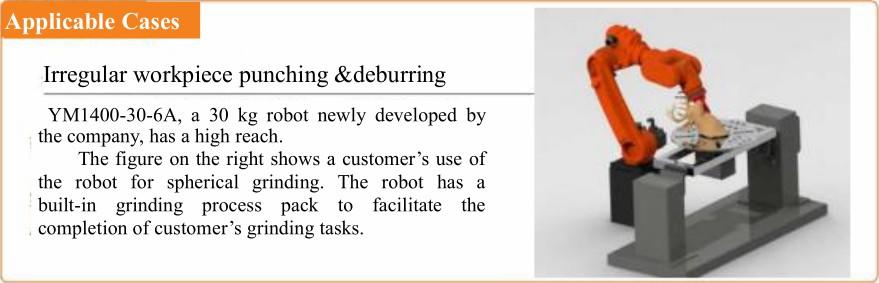

a. Metal processing: In the metal manufacturing industry, grinding robots are used to remove burrs and unevenness in stainless steel, aluminum, copper and other metals on the surface of materials, thereby improving the quality and appearance of the products. For example, the automotive manufacturing industry uses grinding robots to smooth weld seams to ensure smooth welding surfaces and reduce bubbles and weak points, thus improving the structural strength and durability of the car.

b. Automobile manufacturing: The automobile manufacturing industry widely uses grinding robots to process the welds, painted surfaces and glass edges of automobile shells to ensure the perfection and durability of the car's appearance. These robots can automatically identify irregularities and grind and polish them to ensure consistent appearance quality for every car.

c. Woodworking and furniture manufacturing:

Grinding robots are used in the woodworking industry to trim, polish and carve wood to obtain smooth surfaces and complex decorative effects. For example, furniture manufacturers can use these robots to carve exquisite patterns or create artistic effects on wooden furniture, increasing the decorativeness and value of their products.

2. Technical innovation of grinding robots

As technology continues to advance, the grinding robot industry is also constantly developing and improving. Here are some technological innovations in the field of grinding robots:

a. Artificial intelligence and machine learning: Grinding robots are increasingly integrating artificial intelligence and machine learning technology, allowing them to automatically adapt to different materials and shapes to achieve a smarter grinding process. These robots are able to improve their grinding skills through learning, recognize different workpiece and surface types, and automatically adjust grinding parameters. For example, a grinding robot equipped with machine learning algorithms can automatically identify scratches on metal workpieces and adjust the grinding force to eliminate them.

b. Sensing technology: Some advanced grinding robots use sensor technology to monitor the status and surface quality of the workpiece in real time, and automatically adjust the grinding strength and speed. These sensors can measure parameters such as workpiece flatness, temperature, pressure and surface roughness to ensure the stability and consistency of the grinding process. For example, a robot equipped with surface quality sensors can detect any defects on the surface during the grinding process and then automatically adjust the operation to eliminate them.

c. Automation and collaborative robots: The degree of automation is increasing, and some grinding robots can work collaboratively with human operators to improve work efficiency and reduce potential safety risks. This collaborative robot is able to work with operators on complex workpieces or in situations where fine control is required. For example, in aircraft manufacturing, collaborative grinding robots can work with technicians to grind the complex curved surfaces of aircraft wings to ensure high-quality surface treatment.

3. Environmental protection and sustainability

As concerns about environmental protection and sustainability continue to increase, the grinding robot industry is also working hard to reduce its impact on the environment. Here are some areas related to environmental protection and sustainability:

a. Energy-saving technology: Grinding robot manufacturers are developing more energy-efficient robots to reduce energy consumption and use renewable energy for power. For example, some grinding robots feature high-efficiency motors and electronic control systems to reduce energy waste and use renewable energy sources such as solar or wind power to reduce their carbon footprint.

b. Material selection: The grinding robot industry is considering using more environmentally friendly grinding materials to reduce the generation of hazardous waste and increase material recycling rates. For example, some abrasive manufacturers are developing degradable abrasive grains to reduce negative environmental impacts while providing high-quality grinding results.

c. Circular economy: Some companies have begun to adopt a circular economy model to recycle and reuse waste grinding robot parts to reduce resource waste. This practice helps reduce waste generation and reduces the need for new materials. For example, a manufacturer of grinding robots could recycle parts from old robots, repair them and remanufacture them, thereby reducing the cost of handling and disposing of used robots.