1. Automated production and industrial robots

Automated production and industrial robots have become key components of modern manufacturing.

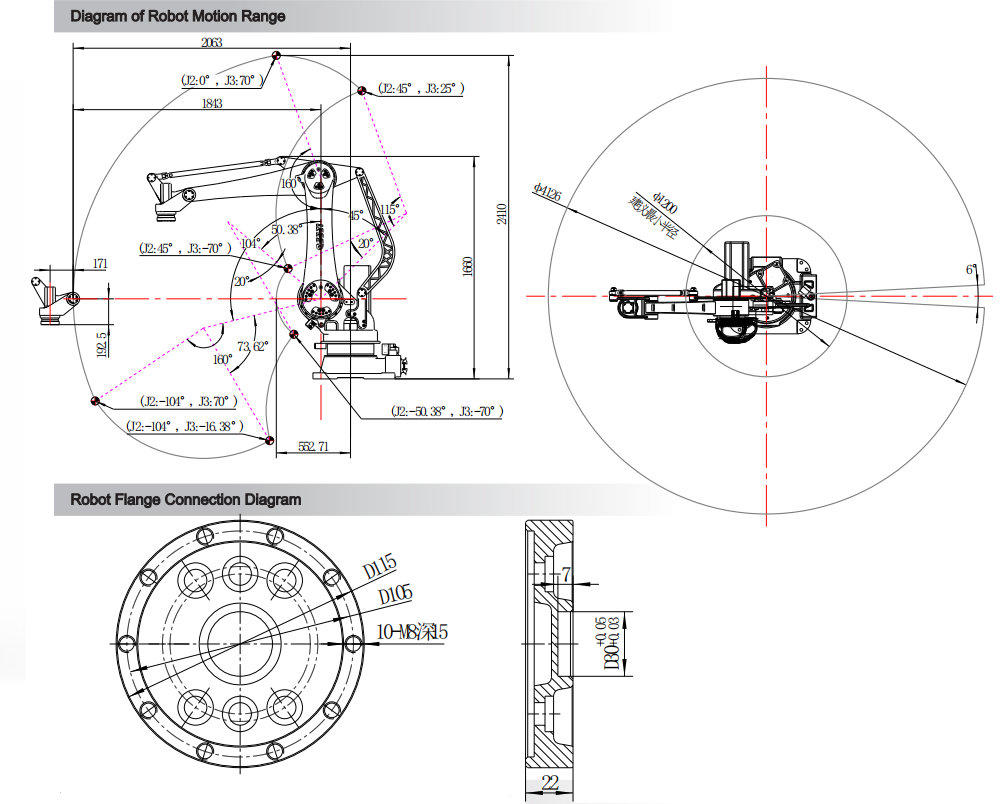

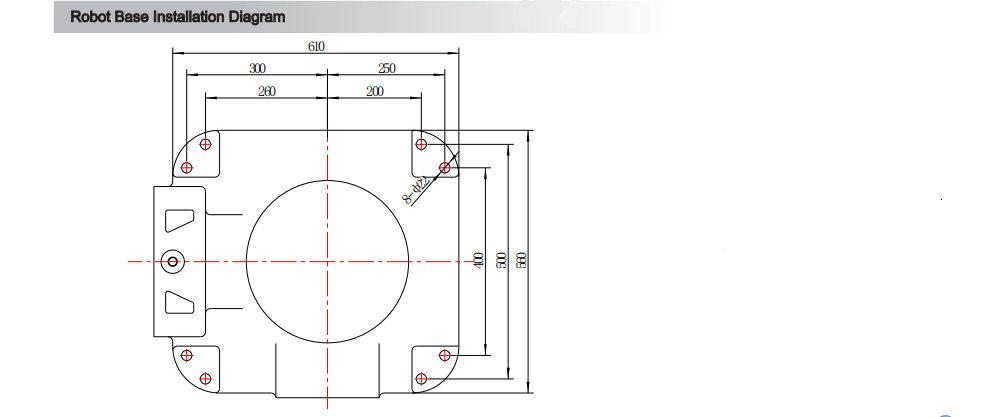

Great handling robot YB2100-100-4A The robot produced in the factory is a vivid representative of this trend. These robots use advanced automation technology to perform a variety of complex tasks, including material handling, assembly, welding and quality control. They can not only improve production efficiency, but also reduce manpower requirements on the production line, reduce costs and improve production quality.

The core of industrial robots is automation. By using sensors, computer vision and advanced programming, these robots can perform complex tasks without human intervention. They can work in hot, cold, hazardous or repetitive environments, reducing employee health risks and fatigue.

Great handling robot YB2100-100-4A factory-made robot represents technological innovation in the field of industrial robots. They feature high precision, speed and programmability and can be customized and configured for different tasks. The robots are also equipped with advanced safety systems to ensure safety when working alongside humans.

In addition, the degree of automation of industrial robots also helps improve the consistency and repeatability of production. This is crucial for manufacturing high-quality products as they reduce quality issues caused by human error. By automating production, manufacturers can more easily meet quality standards and customer demands.

2. Industrial robot application fields

Great handling robot YB2100-100-4A Factory-produced robots are widely used in multiple industries. Here are some of the main application areas:

a.Manufacturing industry

Industrial robots have a wide range of applications in manufacturing. In automobile manufacturing, they are used for body assembly, painting, welding and component processing. Not only do these robots increase productivity, they also improve safety, as they can handle hot, heavy and dangerous tasks without fatigue or distraction. In electronics manufacturing, industrial robots are used for the assembly of electronic components and soldering of printed circuit boards, which help ensure product consistency and high quality.

b. Logistics and warehousing

In the field of logistics and warehousing,

Great handling robot YB2100-100-4A factory-produced robots can be used for loading, unloading, sorting, stacking and transporting goods. They can automate logistics tasks in warehouses, thereby improving logistics efficiency, reducing operating costs, and shortening delivery times. This is especially important in the rapidly changing market and e-commerce industry.

c. Healthcare and life sciences

Industrial robots also play a key role in the medical and life sciences sectors. In the operating room, they are used for precise surgical procedures such as minimally invasive surgery and machine-assisted surgery. This helps improve surgical accuracy, reduce medical risks, and shorten recovery time. In addition, industrial robots are used in laboratories to automate experiments and sample processing, thereby accelerating the process of research and diagnosis.

d. Agriculture

In modern agriculture, industrial robots are used to automate planting, harvesting and farmland management. For example, self-driving tractors can till the soil, plant and harvest crops autonomously without the need for human intervention. This can increase agricultural production efficiency, reduce reliance on agricultural labor, and help meet global food demand.

The versatility of industrial robots makes them suitable for a variety of applications, driving innovation and efficiency improvements in these industries.

3. Future trends and challenges

The industrial robot industry is still evolving, and there are some key trends and challenges in the future:

a. Human-machine cooperation

Industrial robots of the future will work more with humans rather than just operating in closed work areas. This will require smarter security systems and human-machine collaboration technology. For example, flexible robots and perception control systems can make it easier for robots to adapt to different tasks and work environments while maintaining a safe distance from humans.

b. Data-driven decision-making

Industrial robots will use big data and artificial intelligence to make smarter decisions in response to changes in production lines and demand fluctuations. By analyzing sensor data and production information, robots can automatically adjust their operations to maximize efficiency and quality. This will help manufacturers better respond to changes in market demand and reduce production interruptions and waste.

c. Environment and Sustainability

As concerns about environmental sustainability increase, industrial robot manufacturing will be challenged to reduce energy consumption and reduce waste. This could lead to greener and sustainable robot design and manufacturing. For example, the environmental impact of robots can be reduced by using energy-saving materials, more energy-efficient motors, and recycling technologies. In addition, industrial robots can play a greater role in recycling and waste treatment, helping to reduce the ecological footprint of manufacturing.