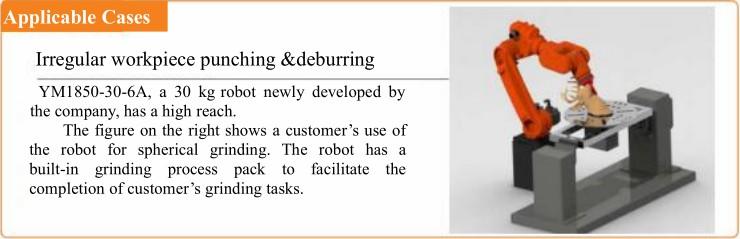

1.Introducing the YM1850-30-6A Grinding Series Robot

In the rapidly evolving world of industrial automation, the

YM1850-30-6A Grinding Series Robot has emerged as a leading innovation, revolutionizing precision grinding applications across industries.

The YM1850-30-6A Grinding Series Robot is designed to excel in applications demanding precision and efficiency. Its adaptability and commitment to maintaining the highest quality standards make it a favored choice for manufacturers looking to optimize their grinding processes.

Key Features of the YM1850-30-6A Grinding Series Robot:

Precision Grinding: At the core of the YM1850-30-6A's capabilities is its precision grinding. Equipped with advanced sensors and artificial intelligence, it can consistently perform highly precise grinding operations. This level of accuracy is vital in industries where product quality is paramount. For example, in the aerospace industry, turbine blades require meticulous grinding to meet stringent standards. The YM1850-30-6A ensures each blade's surface is flawless.

Versatility Across Materials: One of the standout features of this robot is its ability to handle a wide range of materials. Whether it's metals, composites, ceramics, or other materials, the YM1850-30-6A adapts to the specific demands of the task. In an automotive manufacturing plant, where various materials are used in different parts, the robot can seamlessly transition from grinding metal components to composite parts without compromising efficiency.

Safety and Efficiency: Safety in industrial settings is paramount. The YM1850-30-6A is designed with built-in safety features to ensure safe collaboration between human operators and the robot. This not only enhances overall productivity but also minimizes the risk of accidents. In a factory environment, the robot can work alongside human employees, sharing tasks and improving overall efficiency. For instance, in a general manufacturing plant, it can work collaboratively with operators to grind intricate components, ensuring high quality and efficiency.

2.The Technological Advancements of the YM1850-30-6A

In an age driven by technological innovation, the YM1850-30-6A stands out as a testament to progress in the field of industrial robotics.

Artificial Intelligence and Machine Learning:

Artificial intelligence and machine learning are integral to the YM1850-30-6A's capabilities. Through AI-driven algorithms, the robot adapts to different materials and surface conditions, continuously refining its grinding parameters. It learns and adjusts in real-time, delivering optimal performance. For example, in a metalworking application, the robot can identify surface irregularities and automatically adjust its grinding force and speed to eliminate imperfections, ensuring a consistently high-quality finish.

Sensing Technology:

The robot is equipped with advanced sensing technology, allowing it to monitor the workpiece's condition and surface quality throughout the grinding process. This real-time feedback enables the robot to make instant adjustments, maintaining consistent results. In the aerospace industry, where precision is critical, the robot can detect any deviations in the surface of a turbine blade and make immediate adjustments to meet precise specifications.

Collaborative Operation:

Collaborative operation is a key feature of the YM1850-30-6A, and it plays a pivotal role in enhancing industrial productivity. The robot is designed for safe and efficient collaboration with human operators. This feature is particularly valuable in industries where precision and quality control are essential. In an automotive manufacturing facility, the robot can collaborate with human workers to grind and finish intricate components, ensuring a high level of quality. It seamlessly integrates with the production process, providing flexibility and improving overall productivity.

3.Environmental Responsibility and Sustainability

Sustainability is a pressing concern in today's industrial landscape.

Energy-Efficient Design:

Energy efficiency is a key focus in the development of the YM1850-30-6A. The robot is engineered to minimize energy consumption, contributing to cost savings and a reduced environmental footprint. For example, in large-scale manufacturing facilities, where energy costs are substantial, the robot's energy-efficient design can lead to significant savings while reducing carbon emissions.

Eco-Friendly Materials:

Manufacturers are increasingly employing eco-friendly and recyclable materials in the construction of the YM1850-30-6A. This approach reduces the environmental footprint of the robot and aligns with the broader goals of sustainable manufacturing. For instance, the robot's casings and components may be constructed using recycled materials, reducing waste and conserving resources.

Circular Economy Practices:

Adopting circular economy practices, some companies are reusing and recycling components of older robots. This not only minimizes waste but also reduces the demand for new materials. For instance, a manufacturing plant might refurbish and reassemble older YM1850-30-6A robots, extending their lifespan and promoting sustainability.