1. Precision and Speed

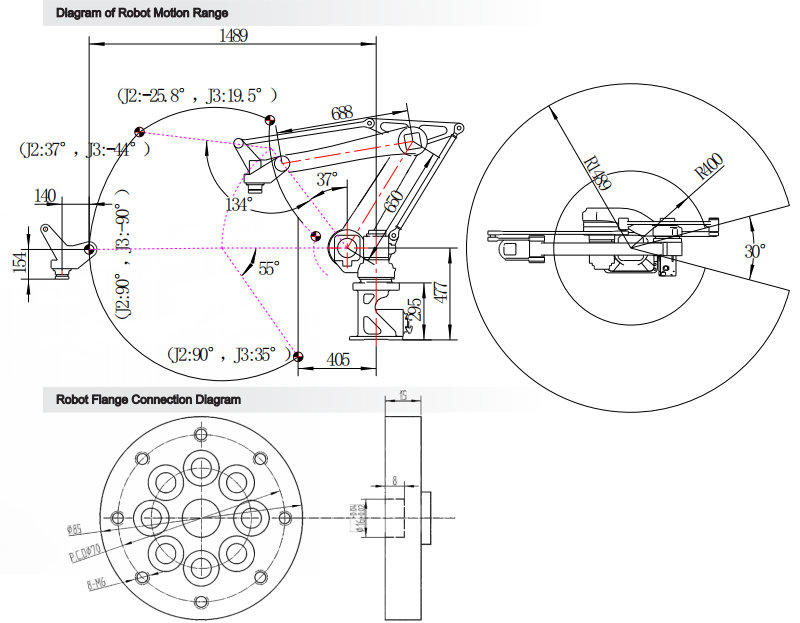

The YB1500-10-4A stands out with its remarkable precision and speed. This robot's ability to perform tasks with micrometer-level accuracy, even in high-speed operations, is a game-changer for industries requiring the utmost precision. This level of accuracy ensures that manufacturing processes meet the most stringent quality standards.

The robot achieves this precision through a combination of advanced sensors and control systems. These sensors allow it to adapt to changes in the environment, ensuring consistent performance even when working in dynamic conditions. The robot's speed is equally impressive; it can complete tasks swiftly, reducing cycle times and improving overall production efficiency.

2. Payload Capacity

One of the standout features of the YB1500-10-4A is its substantial payload capacity, capable of handling up to 10 kilograms of weight. This versatility is invaluable in various industries, as it can accommodate a range of payloads, from small and delicate components to larger and bulkier assemblies.

The robot's adaptable payload capacity makes it an ideal choice for applications in automotive manufacturing, electronics assembly, and logistics. In an automotive assembly line, for example, the robot can handle everything from tiny electronic components to larger engine parts, streamlining the entire production process.

3. User-Friendly Interface

Ease of use is a hallmark of the YB1500-10-4A, thanks to its intuitive user interface. This interface allows for straightforward programming and operation, making it accessible to both experienced and novice operators. The robot can be quickly programmed to perform a wide variety of tasks, and its adaptability ensures it can excel in small-batch, high-mix manufacturing environments as well as high-volume production lines.

The user-friendly interface minimizes the learning curve for operators and programmers, enabling them to rapidly adapt to changing production needs. This feature reduces the overall cost of ownership, as it reduces the time and resources required for training and setup.

Applications of the YB1500-10-4A Handling Series Robot

The YB1500-10-4A handling series robot is a versatile tool that finds applications in various industries.

1. Pick-and-Place Operations

The YB1500-10-4A shines in pick-and-place operations, where it can rapidly and accurately move items from one location to another. This capability is particularly valuable in industries like electronics and consumer goods manufacturing, where precise placement of components is crucial for product quality.

In electronics assembly, the robot's precision is paramount when picking up and placing delicate components on circuit boards. Its ability to execute these tasks at high speeds not only improves production efficiency but also reduces the risk of defects due to human error.

2. Material Handling

In warehouses and logistics, the YB1500-10-4A is employed to streamline material handling tasks. Whether it's loading and unloading pallets, organizing inventory, or transporting goods within a facility, this robot ensures that materials are moved with precision and speed. This significantly reduces labor costs and increases overall operational efficiency.

In a logistics environment, the robot's adaptability shines. It can handle different-sized packages, efficiently stack goods on pallets, and transport them to designated locations. This level of automation minimizes the need for manual labor, mitigating the risk of injuries and errors, and optimizing warehouse operations.

3. Assembly and Inspection

The YB1500-10-4A also finds applications in assembly and inspection processes, particularly in industries where precision is of utmost importance, such as automotive and aerospace.

In an automotive assembly line, the robot can efficiently assemble intricate components with exceptional accuracy. Its precision is instrumental in ensuring that critical parts are joined correctly, contributing to the overall quality and safety of the finished vehicle. Additionally, it can be used for inspection tasks, helping to identify defects or deviations in the assembly process, thereby ensuring consistent product quality.

Best Practices for Handling Series Robots YB1500-10-4A

1. Comprehensive Training

Operators and programmers should undergo comprehensive training to understand the robot's capabilities, programming techniques, and safety protocols. A well-trained team can maximize the robot's potential while ensuring a safe working environment.

Training programs should cover various aspects of robot operation, including programming, troubleshooting, and safety procedures. It's also important to provide ongoing training to keep up with any software updates or enhancements that may improve the robot's performance and capabilities.

2. Regular Maintenance

Scheduled maintenance and calibration are crucial for the robot's long-term performance. Regular inspections and maintenance routines prevent unexpected downtime and extend the robot's lifespan.

Maintenance tasks include checking and calibrating sensors, verifying the integrity of mechanical components, and cleaning and lubricating moving parts. Additionally, software updates should be applied to keep the robot's programming and control systems up to date. These routine maintenance activities are essential for preventing costly breakdowns and ensuring that the robot operates at its full potential.

3. Continuous Monitoring

Implementing a robust monitoring system is essential to track the robot's performance and quickly identify any irregularities. Proactive monitoring can prevent potential issues and optimize efficiency.

Modern robots are often equipped with built-in diagnostic and monitoring features, making it easier to track their performance. In addition to these built-in capabilities, it's advisable to implement a comprehensive monitoring system that can collect and analyze data on the robot's activities and performance. This data can be used to identify trends, predict maintenance needs, and improve overall operational efficiency.