Traditional manual welding methods are in many cases inefficient and susceptible to human factors. In traditional methods, welders need to operate the welding gun for a long time, which not only consumes physical strength, but is also susceptible to fatigue and instability. This results in unstable welding quality and relatively low production efficiency.

The key point is that the Welding Robot Arm YH1500-6-6A not only surpasses manual welding in speed, but also maintains excellent quality. Welding precision and consistency are critical to producing high-quality welded joints, and robots can ensure every weld is consistent, reducing scrap rates.

We need to deeply understand how the robot arm achieves high-efficiency welding. First of all, it is equipped with an advanced welding control system that can monitor welding parameters in real time and automatically make adjustments to ensure the best welding results. In addition, the robot arm has an excellent motion control system that can execute welding paths with extremely high speed and precision, saving time.

The robot is also able to quickly switch welding tasks between different workpieces without the need for manual setup. This versatility makes it suitable for a variety of different welding needs, increasing production line flexibility. In addition, it can perform difficult welding tasks, such as welding in tight spaces, which are difficult for manual welders to perform.

Welding Robot Arm YH1500-6-6A provides a revolutionary welding solution that improves both efficiency and welding quality. This makes it a powerful tool in the manufacturing industry that is expected to replace traditional manual welding in the future, thereby increasing the productivity and competitiveness of the entire industry.

2. How to achieve efficient welding? What are the key technologies of Welding Robot Arm YH1500-6-6A?

To achieve efficient welding, the key lies in the key technology of the robot arm. What key technologies and innovations does

Welding Robot Arm YH1500-6-6A use to achieve excellent welding efficiency?

The robot arm uses an advanced welding control system. This system can monitor welding parameters such as welding current, voltage, welding speed, etc. in real time and automatically adjust as needed. This real-time feedback and control system ensures quality and stability every weld.

The robot arm is also equipped with advanced sensing technology that can detect the position and shape of the workpiece. This enables the robot to automatically adapt to the welding needs of different workpieces without the need for manual setup. This saves time and also reduces the impact of human factors on welding quality.

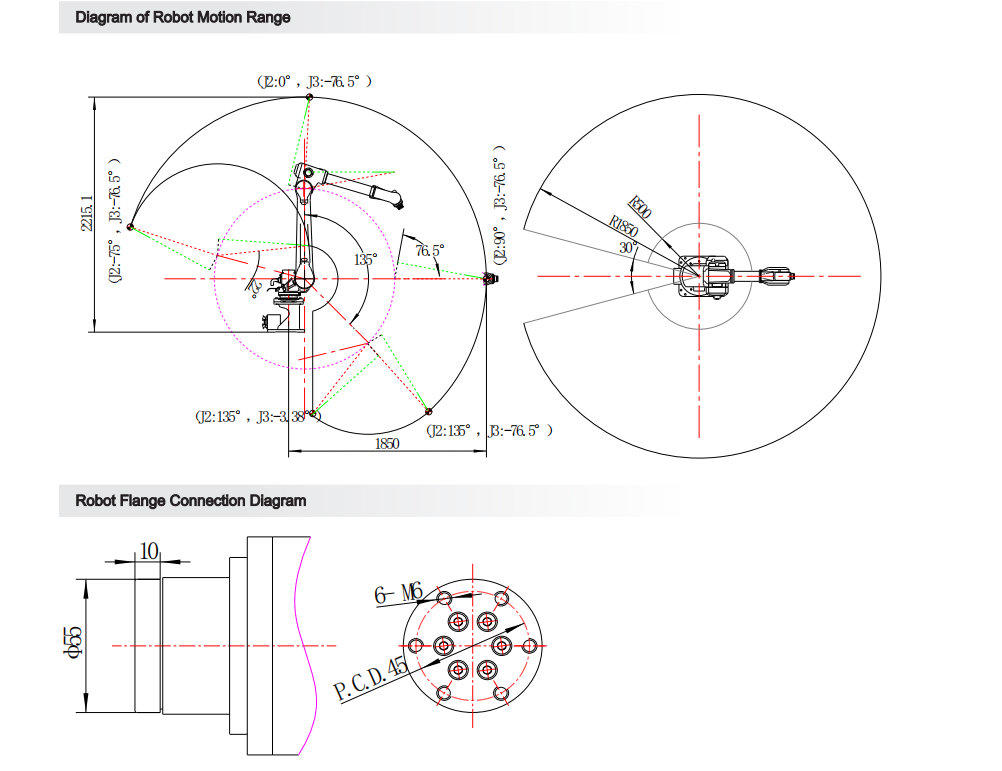

The motion control system of the robot arm is also key to achieving efficient welding. It saves time by executing welding paths with extreme speed and precision. This means that the robot can complete the welding task in a shorter time, improving production efficiency.

Another key technology is the versatility of the robot arm. It can perform a variety of different types of welding tasks, from ordinary welding to difficult welding operations such as welding in tight spaces. This versatility enables it to adapt to different welding needs, thereby increasing the flexibility of the production line.

The automation capabilities of robotic arms are key to efficient welding. It can quickly switch welding tasks between different workpieces without the need for manual setup, thus reducing downtime. This automation capability not only increases efficiency but also reduces costs.

The key technologies of Welding Robot Arm YH1500-6-6A include advanced welding control system, advanced sensing technology, precise motion control system, versatility and automation capabilities. Together, these technologies achieve efficient welding, improve production efficiency, improve welding quality, and bring new opportunities to the manufacturing industry.

3.Welding Robot Arm YH1500-6-6A: What is the trend of the welding industry in the future?

As the manufacturing industry continues to grow, so does the welding industry. Does Welding Robot Arm YH1500-6-6A represent the future trend of the welding industry?

With the wide application of

Welding Robot Arm YH1500-6-6A, traditional manual welding may gradually be replaced by automated welding. This will mean that more welding tasks will be completed by robots, thereby increasing production efficiency, reducing labor costs, and reducing scrap rates. This trend will further promote the development of the welding industry in the direction of automation.

As robotics technology continues to develop, the performance of robotic arms will continue to improve. Future robotic arms may be more precise, flexible and intelligent, able to perform more types of welding tasks and even work in more challenging environments. This will provide more opportunities for innovation and development in the manufacturing industry.

The emergence of Welding Robot Arm YH1500-6-6A will also encourage more manufacturing companies to adopt automation technology. This will improve the automation level of the entire manufacturing industry and accelerate industrial upgrading and development.

As machine learning and artificial intelligence continue to advance, robotic arms may become even smarter. They can learn and adapt to the needs of different welding tasks, making decisions and adjustments based on actual conditions. This will further improve welding quality and efficiency.