1.A New Era in Robotics: Collaborative Robot Arms

The emergence of collaborative robot arms represents a remarkable leap forward in the world of robotics. These systems are designed to work alongside human operators in shared workspaces, unlocking a multitude of applications across various industries. From manufacturing and healthcare to logistics and research, collaborative robot arms are transforming the way we work and interact with automation. Central to the success of these robots is the robot joint, a critical component that significantly impacts the machine's functionality, precision, and, most importantly, safety.

2.The Anatomy of a Robot Joint

The robot joint is the cornerstone of collaborative robot arms, enabling them to replicate the dexterity and flexibility of human arms. These joints are responsible for the articulation and movement of the robot's end-effector, such as a gripper or tool. Understanding the anatomy of a robot joint is fundamental to appreciating its role in this burgeoning field of robotics. A robot joint comprises several essential components:

Actuators: Powering Precision and Motion

Actuators are the powerhouse behind the movement of robot joints. They convert energy into motion, making it possible for collaborative robot arms to perform tasks with precision and efficiency. Various types of actuators are employed, each with its own advantages and applications. Electric motors are a popular choice due to their accuracy and ease of control. Pneumatic cylinders and hydraulic systems may be selected for applications that require high force output.

Sensors: Enabling Perception and Adaptation

Sensors are the sensory organs of a robot joint, allowing it to perceive and interact with its environment. Collaborative robot arms are designed to work safely alongside humans, and sensors play a crucial role in ensuring this. Encoders track joint positions with high accuracy, enabling precise control. Accelerometers detect changes in acceleration, aiding in stability and safety. Force sensors can register external forces, allowing the robot to react in real-time to avoid collisions or perform delicate tasks. Vision systems provide visual feedback, enabling robots to identify and interact with objects and people in their vicinity.

Materials and Construction: Balancing Strength and Weight

The materials used in the construction of robot joints are carefully selected to strike a balance between strength, weight, and durability. Lightweight materials like aluminum or composite materials are commonly chosen for robot joints. Reducing the weight of the robot arm can enhance its overall safety in collaborative settings, as lighter arms are less likely to cause harm in case of contact with a human operator.

3.The Advancements in Robot Joint Technology

Recent years have witnessed substantial advancements in robot joint technology aimed at improving the performance and safety of

Robot Joint For Collaborative Robot Arm. These developments are shaping the future of automation and enhancing the potential of robot joints:

Compliance and Force Control: Real-time Adaptation

Modern robot joints are equipped with advanced force sensors and control algorithms, enabling real-time adaptation to external forces. This compliance and force control capability is a game-changer in collaborative robotics, as it allows the robot arm to work closely with humans and interact with objects in unpredictable environments. Should the robot encounter unexpected resistance, it can immediately adjust its movements to avoid injury or damage. This level of responsiveness and adaptability is vital for applications that require close human-robot collaboration, such as assembly and quality control tasks.

Interconnectivity and Communication: The Industry 4.0 Integration

Collaborative robot arms often form a vital part of larger automation systems. In the era of Industry 4.0 and the Internet of Things (IoT), robot joints are equipped with communication capabilities that allow them to seamlessly interact with other machines, controllers, and human operators. This interconnectedness significantly enhances the efficiency and flexibility of robot arms. These robots can adapt to changing production requirements, receive commands remotely, and provide real-time data to operators and centralized control systems. It opens up new horizons for industries seeking agile and data-driven automation.

Modular Design: Streamlined Maintenance and Adaptation

A modular design approach is gaining traction in the development of robot joints. This design philosophy focuses on making robot joints easier to maintain and upgrade. By breaking down the robot joint into modular components, maintenance and upgrades become more straightforward, reducing downtime and costs associated with repairs. It also simplifies the process of adapting the robot arm to different tasks by merely swapping out specific components. The modularity of robot joints adds to the flexibility and scalability of collaborative robot arms, making them versatile assets for industries that require agility and rapid reconfiguration.

The evolution of robot joints for collaborative robot arms is pivotal in ushering in a new era of automation and collaboration between humans and machines. These components are key to enhancing efficiency and flexibility in a wide range of industries. With continuous innovation and integration of advanced technologies, the future promises even more remarkable developments in this field, making collaborative robot arms an integral part of the evolving landscape of modern manufacturing, healthcare, logistics, and beyond. The collaboration between humans and robots is not just a vision anymore; it's a reality reshaping industries and workplaces.

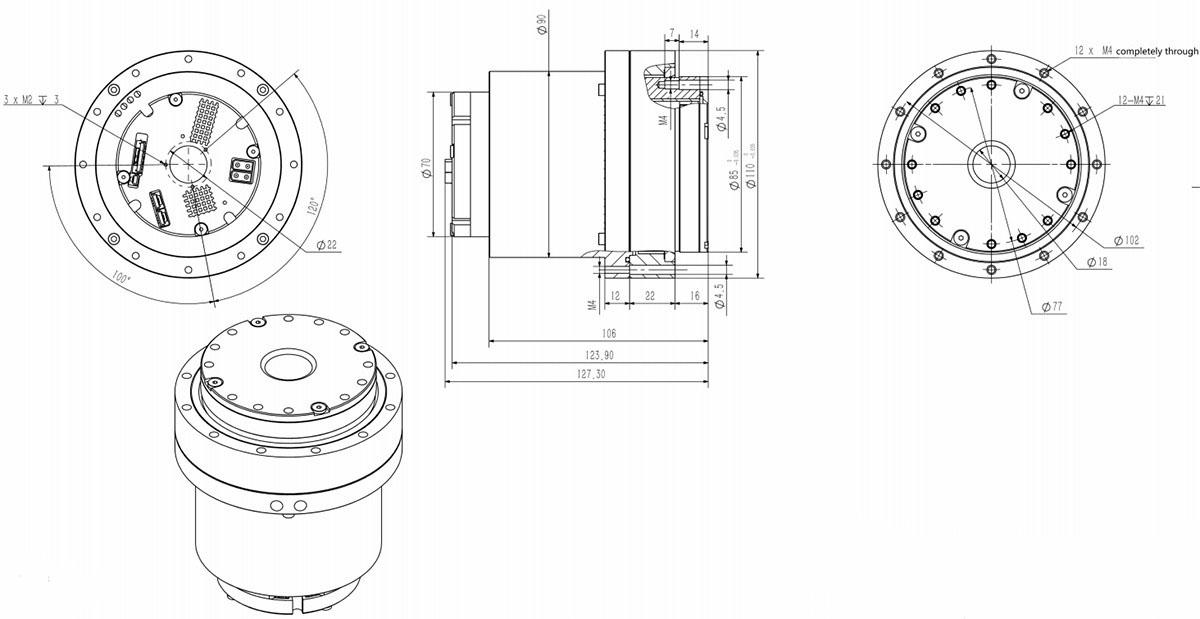

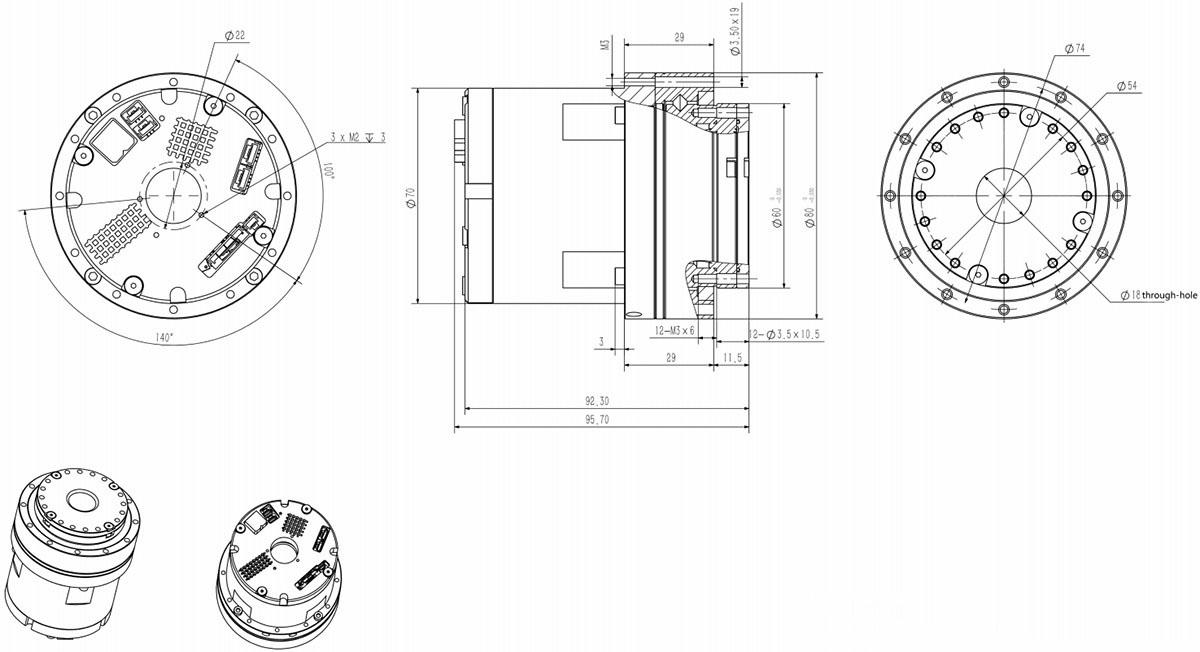

eRob 70I

eRob 70I